Intrepid Potash continues to Increase Potash Production as Potash Prices Continue to Rise

Anson Resources Builds on Successful Lithium Pilot at Green River with Commencement of Resource Conversion; 44% increase in LCE Grades and MOU with POSCO Holdings all Recently Announced

VANCOUVER, BRITISH COLUMBIA / ACCESS Newswire / July 8, 2025 / American Critical Minerals Corp. (“American Critical Minerals” or the “Company“) (CSE:KCLI)(OTCQB:APCOF)(Frankfurt:2P3) is pleased to highlight recent positive developments reported by Intrepid Potash, Inc. (NYSE: IPI) and Anson Resources Ltd. (ASX: ANS) at their respective Paradox Basin operations close to the Company’s flagship Green River Project.*

Management Commentary

Simon Clarke, President and CEO stated, “it is highly encouraging to see continuing increases in the Potash Price and to see the ongoing improvements that Intrepid Potash is implementing to optimize its operations with resulting increases in production and improved financial performance. As a near neighbor in the Paradox Basin and targeting the same potash cycles that are being produced by Intrepid at the Moab Mine utilizing latest horizontal solution mining techniques, we are highly encouraged to see strength not only in the Sector, but also in our backyard.

At the same time, Anson continues to make great progress developing and de-risking its lithium projects which could not be closer to our own Green River Project sandwiched between Anson’s two projects. It is now clear that this part of the Paradox Basin holds major amounts of contained lithium which can be successfully extracted to make battery grade lithium at potentially industry leading operating costs. We commend the work that Anson has done and continues to do quickly and efficiently, and we are pleased with our decision to lock up the lithium and bromine rights across our Project area and to ensure that we are permitted to drill for both Potash and Lithium and associated by products. While the process to secure potash permits did take several years, the evolution of the Paradox Basin as a major source of Lithium Brines over the same timeframe means we now have a Project rich in two critical minerals rather than just the original one.”

Potash In America / Recent Developments

Intrepid continues to be the only producer of Muriate of Potash (“MOP”) in the US, producing approximately 3.5% of US annual MOP Consumption. Intrepid was originally formed to acquire the potash operations in Moab in 2000 from the Potash Corporation of Saskatchewan; the Moab mine was originally built in the 1960s and has operated for over 50 years. Intrepid was the first company to utilize horizontal drilling technology commonly used in the oil and gas industry to raise and stabilize potash production at Moab, Intrepid’s first operating mine. Intrepid continues to successfully utilize Solution Mining at Moab targeting Potash Cycles 5 and 9, the same cycles being targeted by American Critical Minerals at our Green River Potash and Lithium Project in close proximity to the Moab Mine. For full details on Intrepid and the above facts see: https://www.intrepidpotash.com*

Recent Potash Highlights*:

-

Spot MOP prices have risen approx. 25% from $292 in December 2024 to $363.13 on June 30 2025, and continue to rise on increasing global demand and geopolitical events

-

Q1 2025 Results from Intrepid Potash show a 7% increase in potash production (93,000 tons) and a 39% surge in potash sales volumes (103,000 tons)

-

Intrepid Potash continues to invest significantly in increasing production and optimizing its operations reflecting robust market demand

-

For full details of Intrepid Potash Q2 Results see: https://investors.intrepidpotash.com/news/news-details/2025/Intrepid-Announces-First-Quarter-2025-Results/default.aspx

-

With a focus on the same Potash Cycles as Intrepid, the Company has a 43-101 Exploration Target of 600 million to 1 billion tonnes of sylvinite (most important source for the production of potash in North America) with average grades ranging from 19% to 29% KCl.

A report titled “NI 43-101 Technical Report – Green River Potash Project, Grand County, Utah, USA”, prepared by Agapito Associates Inc., and dated effective September 12, 2012, quantifies the Green River Potash Project’s potash exploration potential in the form of a NI 43-101 Exploration Target. The Exploration Target estimate was prepared in accordance with the National Instrument 43-101 –Standards of Disclosure for Mineral Projects (“NI 43-101“). It should be noted that Exploration Targets are conceptual in nature and there has been insufficient exploration to define them as Mineral Resources, and, while reasonable potential may exist, it is uncertain whether further exploration will result in the determination of a Mineral Resource under NI 43-101. The Exploration Target stated in the Agapito Report is not being reported as part of any Mineral Resource or Mineral Reserve. A copy of the report can be accessed on the corporate website for the Company: www.acmineralscorp.com.

Neighboring Lithium Activity

Anson has been exploring and developing its lithium projects in the Paradox Basin for over 6 years. The Company’s Green River Project is sandwiched between the Anson Paradox Project adjacent to the Company’s land to the South and since 2023, Anson’s Green River Project which is contiguous with the Company’s land to the North. Anson published a DFS on its Paradox Basin Project on which it has a JORC Mineral Resource of 366,737 tonnes of lithium carbonate equivalent (LCE) in the indicated category at a grade of 123 ppm Li and 1,137,500 tonnes inferred at a grade of 109ppm Li, and 1,910,000 tonnes of Bromine in the indicated category and 5,698,700 tonnes inferred at a grade of 2,915 ppm Br.

Anson started building out its Green River Project in 2023 and has an Exploration Target for the Project of 1.1-1.6 Billion Tonnes of Brine Grading 100-150 ppm Li (Source: https://wcsecure.weblink.com.au/pdf/ASN/02890607.pdf ). It also completed and announced results of a highly successful Pilot with Koch Technology Solutions in March 2025. While American Critical Minerals has been focused on permitting potash licenses in recent years, it has been impressed with the de-risking steps taken by Anson and consequently acquired 1094 Placer claims over the entirety of its Green River Project in 2024 to ensure it also has the rights to Lithium and Bromine across its Project. Based on historical well logs and data, it is clear that the same brines that Anson is developing underpin the Company’s Green River Project and Lithium is now a major target for the Company in addition to Potash. Its recent drill permits enable the Company to target both potash and lithium in each hole it drills. For full details on Anson Resources and the above facts see: https://ansonresources.com

Recent Lithium Highlights:

-

On June 13, 2025, Anson announced initial JORC Resource from its Green River Project as it starts converting its large Exploration Target to Resources*:

-

On June 17, 2025, Anson announced44% Higher Lithium Values at Green River Lithium Project after Aquifers Open Up*:

-

Higher-grade aquifers “open up” as well is cleaned by brine extraction process

-

Grades averaged 135mg/l Li – 44% higher than originally reported in maiden JORC Resource

-

In comparison to other lithium brines, Anson confirmed that the contaminants that are hardest to reject are in low concentrations in the Green River Brine – making processing easier

-

Confirmation that the Mississippian Units are a massive brine aquifer rich in lithium,

-

For full details see: https://wcsecure.weblink.com.au/pdf/ASN/02957299.pdf

-

On June 30, 2025, Anson announced signing an MOU to develop a large scale DLE demonstration plant at Green River with POSCO Holdings.

About American Critical Minerals’ Green River Potash and Lithium Project

The Green River Potash and Lithium Project is situated within Utah’s highly productive Paradox Basin, located 20 miles northwest of Moab, Utah and has significant logistical advantages including close proximity to major rail hubs, airport, roads, water, towns and labour markets. It also benefits from close proximity to the agricultural and industrial heartland of America and numerous potential end-users for its products.

The history of oil and gas production across the Paradox Basin provides geologic data from historic wells across the Project, and the wider Basin, validating and de-risking the potential for high grade potash and large amounts of contained lithium. Wells in and around the project reported lithium up to 500 ppm, bromine up to 6,100 ppm and boron up to 1,260 ppm (Gilbride & Santos, 2012). This data is reinforced by nearby potash production and the advanced stage of neighbouring lithium projects. The Paradox Basin is believed to contain up to 56 billion tonnes of lithium brines, potentially the largest such resource in US (Source: Anson Fastmarkets Presentation – https://wcsecure.weblink.com.au/pdf/ASN/02823465.pdf ).The Company also has a 43-101 Exploration Target of 600 million to 1 billion tonnes of sylvinite (the most important source for the production of potash in North America) with average grades ranging from 19% to 29% KCL.**

The Company holds a 100% interest in eleven State of Utah (SITLA) mineral and minerals salt leases covering approximately 7,050 acres, 1,094 federal lithium brine claims (BLM Placer Claims) covering 21,150 acres, and 11 federal (BLM) potash prospecting permits covering approximately 25,480 acres. Through these leases, permits and claims the Company has the ability to explore for potash, lithium and potential by-products across the entire Green River Project (approx. 32,530 acres). The Company is authorized to drill a total of 7 exploratory drill holes across the Project (pending bonding the recently approved 4 drill holes).

Intrepid Potash, Inc. (NYSE: IPI) is America’s largest potash company and only U.S. domestic potash producer and currently produces potash from its nearby Moab Solution Mine, which the Company believes provides strong evidence of stratigraphic continuity within this part of the Paradox Basin (www.intrepidpotash.com). Anson Resources Ltd. (ASX: ASN) has advanced lithium development projects contiguous to the northern boundary of our Green River Project and neighbouring to the south. Anson has a large initial resource, robust definitive feasibility study and has recently completed successful piloting operations through its partnership with Koch Technology Solutions, as well as an offtake agreement with LG Energy Solution. The Anson exploration targets encompass the combined Mississippian Leadville Formation and the Pennsylvanian Paradox Formation brine-bearing clastic layers, which also underlie American Critical Minerals’ entire project area (www.ansonresources.com)*.

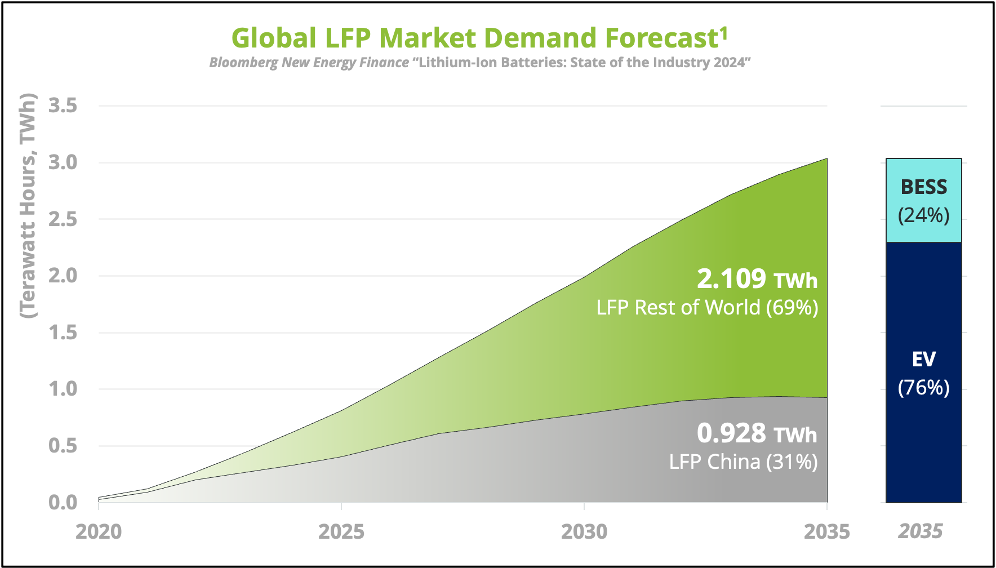

In 2022, the U.S. imported approx. 96.5% of its annual potash requirements with domestic producers receiving a higher sales price due to proximity to market (intrepidpotash.com/ August 15, 2024, Investor Presentation). In March 2024, the US Senate introduced a bill to include key fertilizers and potash on the US Department of Interior list of Critical Minerals which already includes lithium. Recent market estimates suggest that the global potash market is over US$50 billion annually and growing at a compound annual growth rate (“CAGR“) of close to 5%. Annual lithium demand is now estimated to be over 1 million tonnes globally and continuing to grow rapidly.***

Qualified Person

The Technical content of this news release has been reviewed and approved by Dean Besserer, P.Geo., the Chief Operations Officer (“COO“) of the Company and a qualified person for the purposes of NI 43-101.

On behalf of the Board of Directors

Simon Clarke, President & CEO

Contact: (604)-551-9665

*American Critical Minerals’ management cautions that results or discoveries on properties in proximity to the American Critical Minerals’ properties may not necessarily be indicative of the presence of mineralization on the Company’s properties.

**A report titled “NI 43-101 Technical Report – Green River Potash Project, Grand County, Utah, USA”, prepared by Agapito Associates Inc., and dated effective September 12, 2012, quantifies the Green River Potash Project’s potash exploration potential in the form of a NI 43-101 Exploration Target. The Exploration Target estimate was prepared in accordance with the National Instrument 43-101 -Standards of Disclosure for Mineral Projects (“NI 43-101“). It should be noted that Exploration Targets are conceptual in nature and there has been insufficient exploration to define them as Mineral Resources, and, while reasonable potential may exist, it is uncertain whether further exploration will result in the determination of a Mineral Resource under NI 43-101. The Exploration Target stated in the Agapito Report is not being reported as part of any Mineral Resource or Mineral Reserve. A copy of the report can be accessed on the corporate website for the Company: www.acmineralscorp.com.

***United States Geological Survey, Mineral Commodity Summaries, January 2024 (https://pubs.usgs.gov/periodicals/mcs2024/mcs2024-potash.pdf).

Cautionary Statements Regarding Forward Looking Information

This news release contains forward-looking information within the meaning of applicable securities legislation. Forward-looking information is typically identified by words such as: believe, uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking information. Important factors that could cause actual results to differ from this forward-looking information include those described under the heading “Risks and Uncertainties” in the Company’s most recently filed MD&A. The Company does not intend, and expressly disclaims any obligation to, update or revise the forward-looking information contained in this news release, except as required by law. Readers are cautioned not to place undue reliance on forward-looking expect, anticipate, intend, estimate, postulate and similar expressions, or are those, which, by their nature, refer to future events. Such statements include, without limitation, statements regarding future confirmation drilling and its intended outcomes and the intended use of proceeds from the oversubscribed financing. Although the Company believes that such statements are reasonable, it can give no assurances that such expectations will prove to be correct. All such forward-looking information is based on certain assumptions and analyses made by the Company in light of their experience and perception of historical trends, current conditions and expected future developments, as well as other factors management believes are appropriate in the circumstances. This information, however, is subject to a variety of risks and information.

SOURCE: American Critical Minerals Corp.

View the original press release on ACCESS Newswire